1. Taw qhia txog 1060 Aluminium Alloy

1060 txhuas ntawv yog ib lub siab purity aluminium alloy dav lees paub rau nws zoo heev corrosion kuj, thermal conductivity, thiab formability. Muaj kwv yees li 99.6% aluminium, qhov noalloy yog ib feem ntawm 1000 series, uas yog tus yam ntxwv los ntawm tsawg impurities thiab exceptional workability. Nws cov tshuaj muaj pes tsawg leeg ua raws li cov qauv thoob ntiaj teb xws li ASTM B209 thiab GB / T 3880.1, ua kom muaj kev sib luag thiab kev ntseeg siab thoob plaws ntiaj teb kev lag luam.

2. Chemical Composition thiab Microstructure

Cov ntsiab lus tseem ceeb hauv 1060 txhuas yog txwv rau cov khoom siv hlau (Fe ≤ 0.35%) thiab silicon (Si ≤ 0.25%), nrog rau lwm cov impurities nruj me ntsis tswj hauv qab 0.05%. Cov ntsiab lus qis intermetallic no pab txhawb rau nws cov homogeneous microstructure, uas tseem tsis yog-kub-kho tau tab sis zoo heev rau kev ua haujlwm txias. Qhov tsis muaj cov ntsiab lus tseem ceeb xws li tooj liab lossis magnesium ua kom muaj kev pheej hmoo tsawg galvanic corrosion, ua rau nws zoo tagnrho rau ib puag ncig nrog tshuaj lom neeg.

3. Mechanical thiab Physical Properties

1060 txhuas ntawv nthuav tawm lub zog tensile ntawm 90-120 MPa thiab lub zog tawm ntawm 45-60 MPa hauv O-temper (annealed) mob. Nws elongation tus nqi (15-25%) underscores nws superior ductility, ua kom sib sib zog nqus nqus thiab khoov yam tsis muaj cracking. Thermally, nws boasts ib tug thermal conductivity ntawm 237 W / m·K, outperforming feem ntau structural alloys. Tsis tas li ntawd, nws cov hluav taws xob conductivity (61% IACS) ua rau nws qhov kev xaiv zoo tshaj plaws rau kev siv hluav taws xob.

4. Kev kho deg thiab formability

Txhawm rau txhim kho kev ua tau zoo, 1060 cov ntawv txhuas tuaj yeem ua rau kev sib tsoo, dov, lossis annealing kev kho kom ua tiav qib siab xav tau (H14, H18, H24). Nto tiav xws li zeb tiav, txhuam, los yog anodized coatings ntxiv txhim kho corrosion kuj thiab zoo nkauj thov. Cov hlau tsis tshua muaj zog tso cai rau seamless kev koom ua ke rau hauv cov txheej txheem sib sau ua ke, suav nrog stamping, extrusion, thiab yob txoj kev, tsis muaj kev cuam tshuam qhov kev ruaj ntseg.

5. Cov ntawv thov tseem ceeb thoob plaws kev lag luam

A. Electronics thiab Hluav Taws Xob Engineering

Lub siab thermal thiab hluav taws xob conductivity ntawm1060 aluminium ntawvua rau lawv indispensable nyob rau hauv lub dab dej kub, hluav taws xob enclosures, thiab busbar systems. Lawv lub teeb yuag tsis tau ruaj khov ua kom muaj cua sov zoo hauv cov hluav taws xob hluav taws xob thiab LED teeb pom kev zoo.

B. Architectural thiab Kev Tsim Kho

Hauv kev tsim kho, 1060 daim ntawv yog siv rau cov ntaub thaiv phab ntsa, ru tsev panels, thiab sab hauv partitions. Lawv UV tsis kam thiab cov khoom tsis sib nqus ua ke nrog cov kev xav tau niaj hnub architectural rau lub zog-npaum thiab aesthetically pleasing lug.

C. Tsheb thauj mus los thiab tsheb

Cov hlau tsis muaj qhov ntom ntom (2.7 g / cm³) thiab corrosion kuj ua rau nws haum rau cov khoom siv hauv tsheb, suav nrog cov roj teeb, cov roj tso tsheb hlau luam, thiab cov khoom siv sib xyaw. Hauv kev tsheb ciav hlau, nws tau ua haujlwm rau cov vaj huam sib luag sab hauv thiab lub qhov rooj, txo cov tsheb hnyav thaum tswj cov qauv kev nyab xeeb.

D. Kev ua zaub mov thiab ntim khoom

1060 txhuas lub ntsej muag tsis muaj tshuaj lom thiab cov khoom siv tu cev ua raws li FDA thiab ISO 22000 ntawv pov thawj, ua rau nws yog ib qho tseem ceeb hauv cov ntim khoom noj, cov kaus poom, thiab cov tshuaj ntim tshuaj. Nws qhov chaw uas tsis yog-reactive tiv thaiv kev kis kab mob hauv qhov chaw rhiab heev.

E. General Manufacturing

Los ntawm chemical processing tanks mus rau marine khoom,1060 aluminium ntawvmuab dej ntsev corrosion kuj thiab qhov ntev stability, txawm nyob rau hauv hnyav industrial tej yam kev mob.

6. Qhov zoo tshaj qhov sib tw Alloys

Piv rau 6061 los yog 3003 txhuas, 1060 muaj ntau dua purity, qis nqi, thiab superior formability, albeit nrog me ntsis txo lub zog. Nws yooj yim ntawm vuam thiab machining ntxiv txo cov nqi tsim khoom, ua rau nws muaj txiaj ntsig zoo rau kev siv tsis yog qauv.

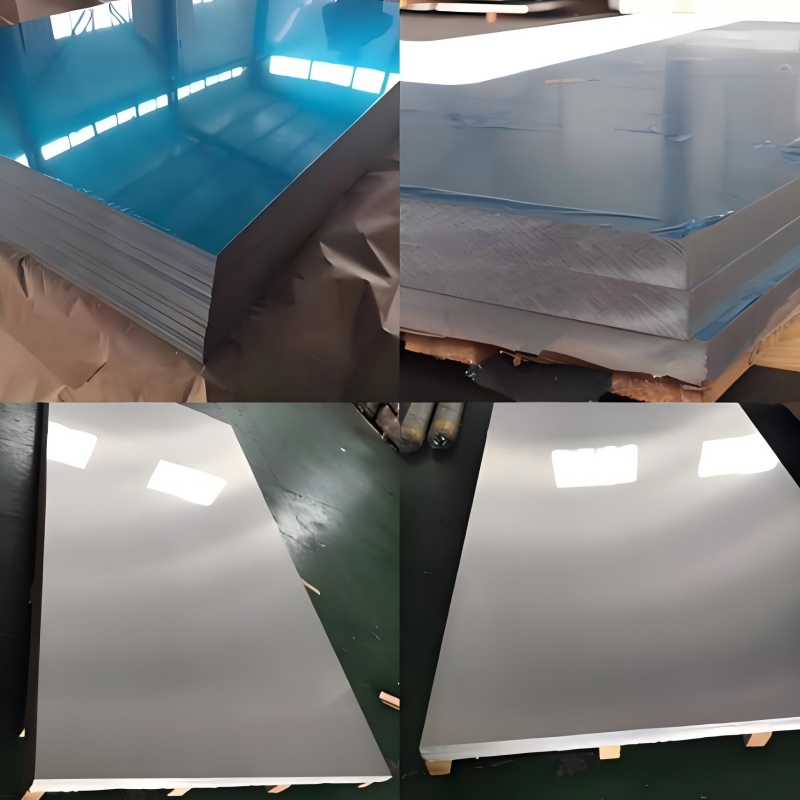

7. Kev lees paub zoo thiab kev tsim kho

Peb 1060 txhuas ntawv yog tsim nyob rau hauv ISO 9001: 2015 thiab ISO 14001: 2015 ntawv pov thawj, kom ntseeg tau raws li ASTM, EN, thiab JIS cov qauv. Peb muab customization nyob rau hauv thickness (0.2-200 mm), dav (50-2000 mm), thiab temper (O, H112, H14) kom tau raws li ntau haiv neeg yuav tsum tau.

8. Vim li cas thiaj xaiv 1060 Cov Ntawv Txhuas?

Rau kev lag luam ua ntej tus nqi-zoo, kev tiv thaiv corrosion, thiab thermal kev ua tau zoo, 1060 txhuas ntawv sawv cev rau cov kev daws teeb meem zoo. Txawm hais tias rau cov khoom siv hluav taws xob siab, kev tsim kho kom ruaj khov, lossis ntim khoom noj khoom haus, peb cov khoom sib xyaw ua ke nrog kev ua tau zoo nrog ntau yam tsis sib xws.

Tiv tauj peb Hnub no

Txhawm rau sib tham txog koj qhov project yuav tsum tau lossis thov cov qauv, hu rau peb pab pawg kws tshaj lij txhuas. Nrog ntau tshaj 10 xyoo kev paubnyob rau hauv aluminium phaj, pas nrig, thiab machining daws, peb xa cov khoom tsim nyog tshaj qhov kev cia siab.

Post lub sij hawm: Nov-20-2025