2000 series aluminium alloy - ntau pab pawg ntawm tooj liab-raws li alloys renowned rau tshwj xeeb lub zog, tshav kub-kho khoom, thiab precision manufacturability. Hauv qab no, peb nthuav dav covcov yam ntxwv tshwj xeeb, kev siv,thiab customized ua muaj peev xwm ntawm 2000 series txhuas, tailored kom tau raws li cov kev xav tau nruj ntawm kev lag luam thoob ntiaj teb.

Lub ntsiab alloy

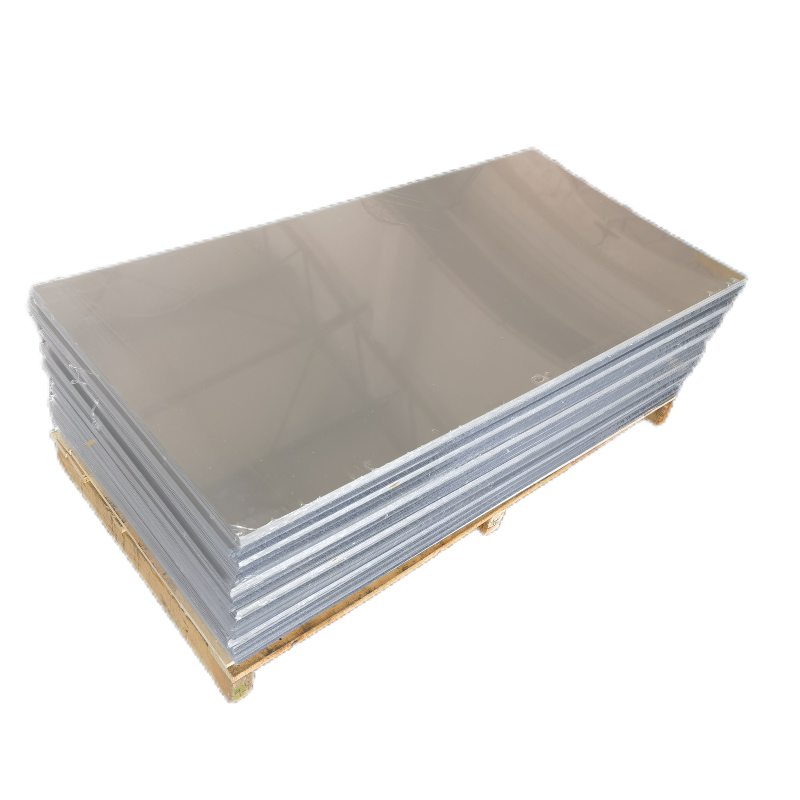

2000 series aluminium alloys (piv txwv li, 2024) yog txhais los ntawm lawv cov tooj liab (Cu) - tseem ceeb muaj pes tsawg leeg (3% ~ 5% Cu), feem ntau ua ke nrog cov ntsiab lus xws li magnesium (Mg), manganese (Mn), thiab silicon (Si).

Cov alloys no muaj cov yam ntxwv hauv qab no:

1. Superior Strength-rau-Weight Ratio

Nrog rau qhov kawg tensile lub zog (σb) tshaj 400 MPa (piv rau cov pa roj carbon tsawg), 2000 series alloys yog qhov zoo tagnrho rau kev siv cov kabmob uas qhov hnyav yog qhov tseem ceeb. Kev kho cua sov (xws li, quenching thiab aging) ntxiv txhim kho hardness thiab mechanical kev ua tau zoo, ua rau lawv cov cua sov kho kom muaj zog ntxiv.

2. Precision Machinability

Nyob rau hauv lub xeev annealed los yog freshly quenched, cov alloys muaj qhov nruab nrab ductility, ua rau seamless fabrication rau hauv complex duab los ntawm cov txheej txheem xws li CNC milling, tig, thiab drilling. Alloy zoo li 2024 muab kev ua haujlwm zoo tom qab ua haujlwm txias, tsim nyog rau cov khoom siv tau zoo.

3. Balanced Corrosion Resistance

Thaum tsis tshua muaj corrosion-resistant tshaj 5000 los yog 6000 series alloys, 2000 series cov ntaub ntawv tuaj yeem txhim kho nrog kev kho deg (xws li, anodizing, chromate conversion txheej) kom txo tau cov kev pheej hmoo corrosion intergranular, ua kom lub neej ntev nyob rau hauv ib puag ncig hnyav.

4. Weldability & Formability

Haum rau qhov chaw vuam thiab ib nrab fusion vuam (nrog kev ceev faj tiv thaiv crystallographic tawg), cov alloys sib npaug formability nyob rau hauv thermal xeev nrog cov qauv kev ncaj ncees nyob rau hauv kawg daim ntaub ntawv.

Core Applications ntawm2000 Series Aluminium Alloys

1. Aerospace:

Cov khoom siv (tis tis, fuselage thav duab, tsaws iav qhov chaw), cov tawv nqaij ntawm lub dav hlau thiab qhov chaw muaj kev ntxhov siab (2024-T4) rau kev lag luam dav hlau, tub rog aircraft thiab drones.

2. Automotive & Tsheb thauj mus los:

Cov khoom ua tau zoo xws li kev sib tw tsheb log, qhov chaw nres tsheb thiab lub teeb yuag chassis (2024) uas xav tau lub zog yam tsis muaj kev cuam tshuam rau kev siv roj.

3. Muaj & Machinery:

Heavy-duty gears, shafts, pwm thiab tooling (2014) rau kev tsim khoom, nrog rau precision qhov chaw rau robotics thiab automation systems.

4. High-End Consumer Khoom:

Cov khoom siv ua kis las hwm (tsheb kauj vab, lub taub hau golf), cov khoom siv hluav taws xob zoo nkauj thiab cov khoom siv vaj tsev tsim nyog yuav tsum muaj qhov sib npaug ntawm kev zoo nkauj thiab kav ntev.

Customized Processing Solutions:

Leveraging xyoo lawm ntawm kev txawj ntse nyob rau hauv txhuas cov khoom thiab CNC machining, peb muab cov kev daws teeb meem kawg-rau-kawg rau 2000 series alloys.

1. Cov Khoom Muag Khoom Muag - Kev tswj xyuas kom zoo:Tag nrho cov ntaub ntawv ua tau raws li cov qauv thoob ntiaj teb (ASTM, ISO, JIS) nrog cov ntaub ntawv pov thawj thiab cov cuab yeej cuab tam cov ntaub ntawv.

2. Precision Machining & Fabrication

Muaj peev xwm: CNC milling, tig, drilling, threading, sib tsoo thiab xaim EDM rau txoj kev geometries nrog nruj tolerances (± 0.01 hli).

Cov kev pabcuam muaj nqis ntxiv: Kev kho deg (anodizing, hmoov txheej, passivation), vuam (TIG, qhov chaw vuam) thiab sib dhos rau cov khoom npaj siv.

3. Customized Engineering Support

Kev sib koom tes tsim kev pab: Los ntawm CAD qauv rau kev tsim qauv, peb pab neeg ua kom zoo dua cov khoom siv thiab kev ua haujlwm kom tau raws li cov kev ua tau zoo thiab cov nqi.

Scalability: Kev daws teeb meem rau cov qauv qis thiab cov khoom ntim siab, txhawb nqa los ntawm cov chaw tsim khoom siab heev thiab kev ua haujlwm lean ntau lawm.

4. Ntiaj teb no Logistics & Ua raws

Fast turnaround: Cov qauv xaj xa tuaj tsis pub dhau 7 ~ 15 hnub, thov ceev nrawm los ntawm kev ua tiav sai.

Kev Ua Raws Cai: RoHS, REACH, thiab aerospace / automotive kev lag luam tshwj xeeb ntawv pov thawj muaj nyob rau ntawm kev thov.

Vim li cas thiaj xaiv Shanghai Miandi rau 2000 Series Txhuas?

1. Material Expertise:Kev nkag siab tob txog2000 series alloy metallurgy xyuas kom meejkev ua tau zoo tshaj plaws rau koj daim ntawv thov.

2. One-Stop Service:Los ntawm cov khoom siv raw khoom mus rau cov khoom tiav, cov khoom kho saum npoo, tshem tawm qhov xav tau ntawm ntau tus neeg xa khoom.

3. Quality Assurance:Kev ntsuas nruj (lub zog tensile, hardness, corrosion kuj) thiab ISO 9001: 2015 ntawv pov thawj lav kev ntseeg tau.

4. Tus nqi sib tw:Direct Hoobkas nqi thiab nqi-zoo machining daws yam tsis muaj kev cuam tshuam zoo.

Npaj txhij los siv lub zog zoo tshaj thiab ntau yam ntawm 2000 series txhuas rau koj qhov project tom ntej? Hu rau Shanghai Miandi Hlau Group Co., Ltd. hnub no rau cov khoom siv thiab cov kev daws teeb meem machining. Peb pab neeg tau mob siab rau xa cov khoom zoo tshaj plaws los ntawm cov khoom siv raw mus rau cov khoom tiav.

Post lub sij hawm: Jun-13-2025